The diesel particulate filter market is experiencing steady growth due to rising regulations set by the Environmental Protection Agency. DPF filters are used on diesel engines to remove particulate matter from exhaust gas in an effort to reduce emissions and address concerns around pollution and air quality. This technology has proven to be effective in controlling diesel particulate emissions – including particle mass and numbers – with tremendous efficiency. They’ve been verified by the EPA and the California Air Resources Board at reducing soot emissions by 85 to 90%. Some also lower hydrocarbons and Carbon Monoxide by up to 90%.

For this reason, there has been an increase in the production and sales of diesel vehicles from a number of different regions with the global diesel particulate filter market expected to grow at CAGR of ~8% over the next few years. This growth provides today’s repair shops with an opportunity for increased service offerings.

While OE recommendations should always be followed, today’s diesel particulate filters usually need to be cleaned every 100,000 to 200,000 miles depending on type of vehicle and driving conditions. Regular maintenance is critical to the life of the filter and surrounding components. It also helps your customers avoid issues with fuel economy, vehicle performance and unexpected downtime.

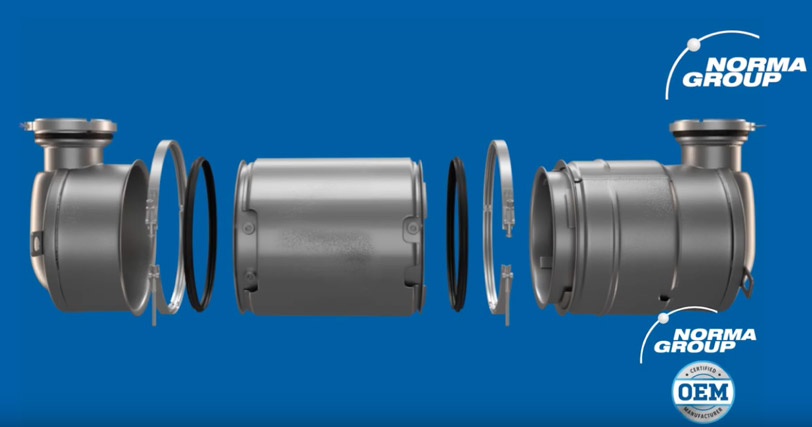

Below is a cutaway of a diesel aftertreatment system. The actual filter is housed between an end cap and the oxidation catalyst and typically has four clamps and four gaskets that help hold it together.

When it comes to cleaning, an OEM approved flow bench test will help confirm the filter’s quality. Filters need to be inspected thoroughly and damage should be noted. Black streaks of soot on the inlet channel or checkerboard patterns, raised substrates or star shape dots on the outlet are signs of a problem.

We always recommend replacing clamps at every cleaning interval too and using OEM quality clamps designed for the harsh environment today’s diesels are exposed to. The DPF system can generate very high temperatures during regeneration and cause some poor quality aftermarket clamps to fail. NORMA clamps are made from the highest quality steel to reduce the possibility of clamp failure. For more, check out our DPF Regulatory Info and Tech Tips video.